Pillow plates

Pillow plates are specialised heat exchanger plates designed to effectively handle thermal management in a wide range of industrial applications. Made from two metal plates welded together by laser welding, pillow plates form a pressure-tight structure. The plates get inflated to create internal channels where the cooling or heating mediums flow through to achieve efficient heat transfer.

Advantages

- The fully automated laser welding process minimises labor costs, ensuring high precision and consistency at a lower expense.

- Thin materials are used to form the pillow shape, significantly lowering material expenses without compromising performance.

- The welding pattern can be customised to control heat transfer parameters, providing exceptional thermal performance tailored to specific needs.

- Their design allows for efficient thermal management in a smaller, lighter form factor compared to traditional solutions.

- Constructed with robust laser-welding techniques, pillow plates are pressure-tight and built to endure demanding industrial environments.

- Suitable for heating, cooling, or heat recovery in a wide range of industries, including food processing, chemical manufacturing, and energy.

Types of pillow plates

DimpleSteel offers two types of pillow plates: single embossed for structural or sanitary product applications, and double embossed for enhanced heat transfer efficiency in demanding applications. Both types are customisable to meet your specific thermal management needs.

Types of pillow plates

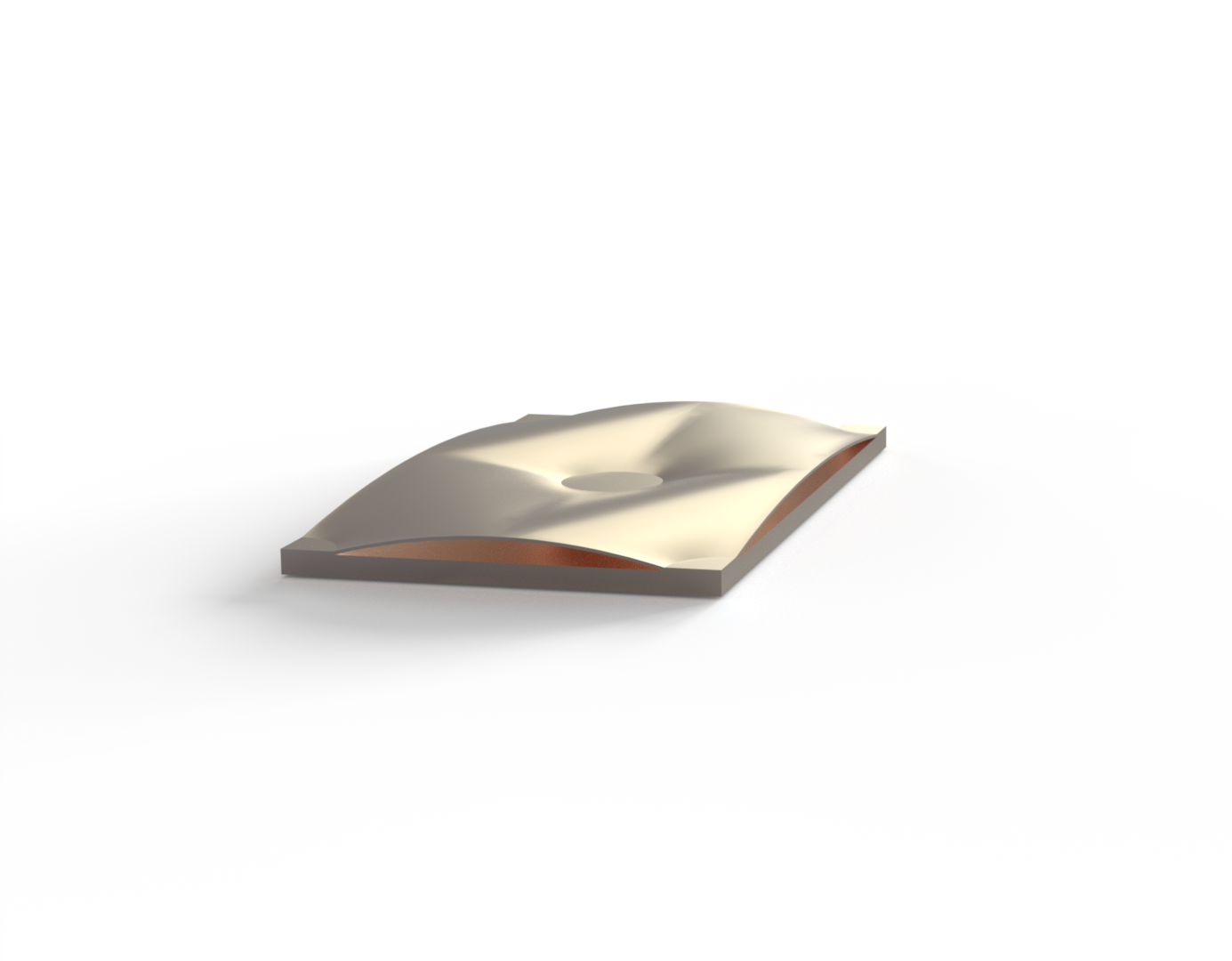

Single-embossed plates: One side remains flat, while the other side is inflated to create a functional surface for mounting or placement in tanks. These plates are ideal for applications where one surface needs to stay smooth.

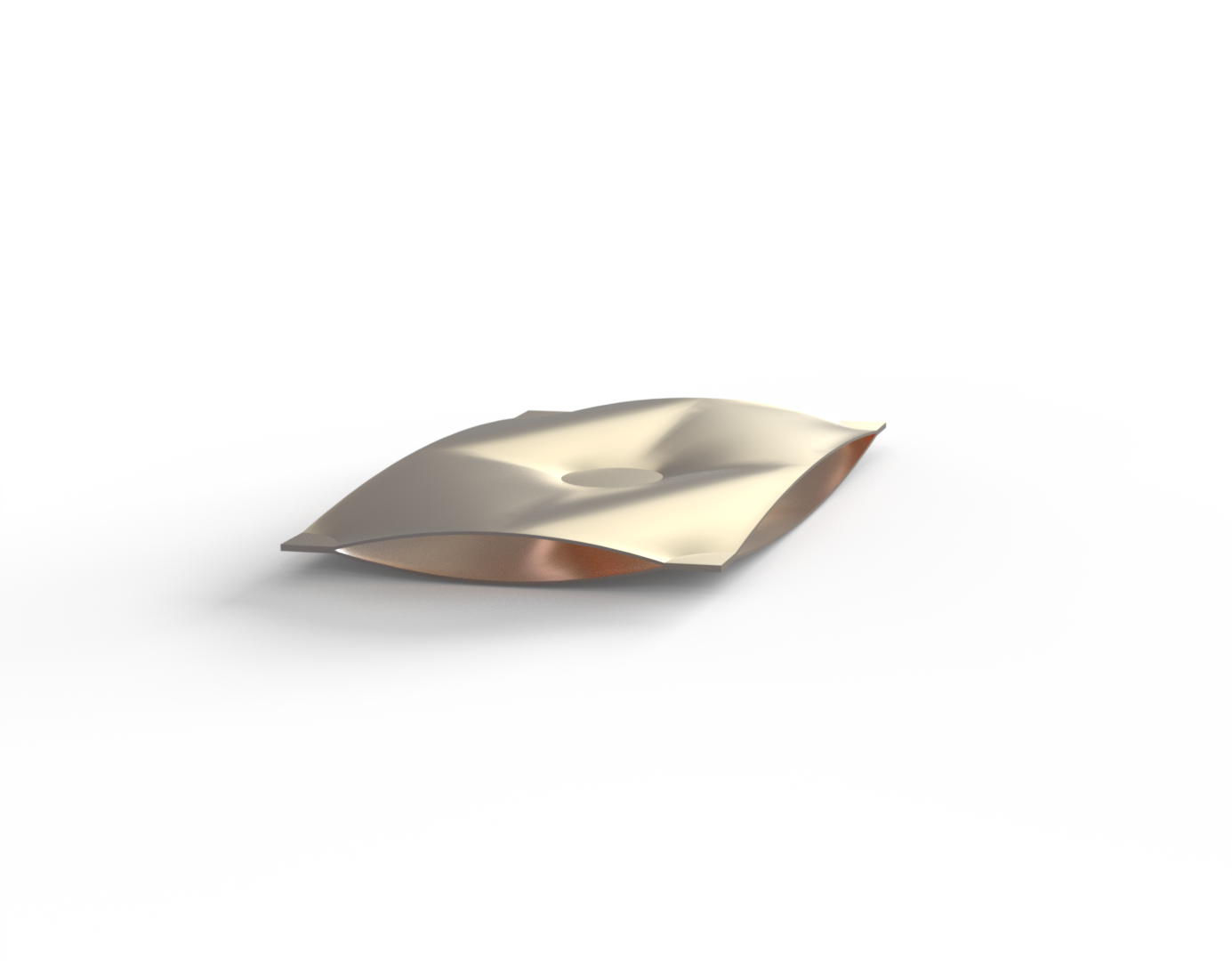

Double-embossed plates: Both sides of the plate are inflated, increasing the surface area for heat exchange. This design is commonly used in immersion or free-standing heat exchangers where enhanced thermal performance is essential.

Steps behind every pillow plate we craft

Pillow plates are made through a precise and automated process that ensures durability, efficiency, reliability, and consistent performance in demanding industrial environments.

Two sheets of metal, typically stainless steel, are cut to the desired dimensions.

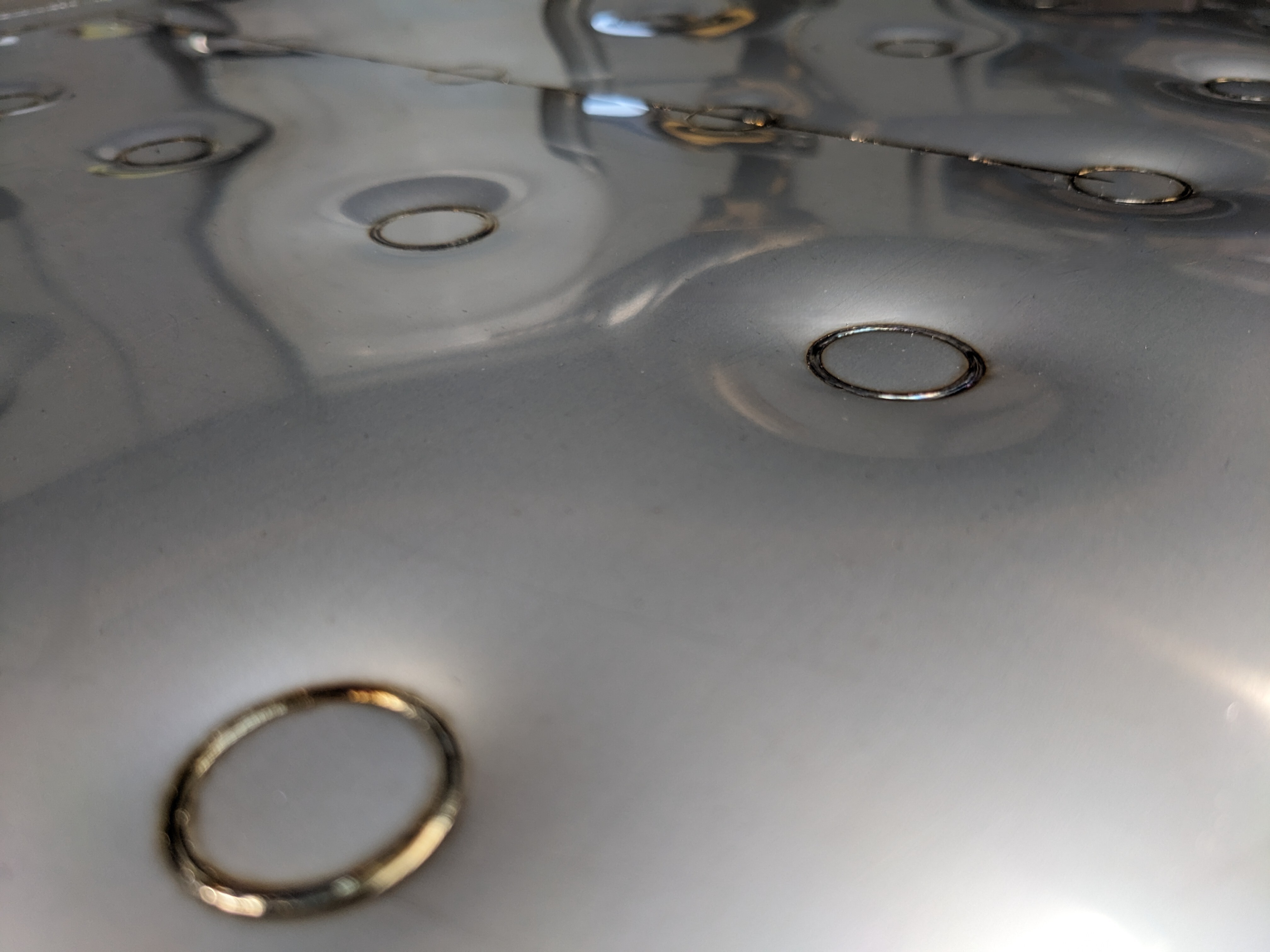

A laser welding machine creates a series of spot welds in a pre-determined pattern on the sheets. These welds define the internal flow channels for heat transfer.

The welded sheets are pressurized, inflating the unwelded sections to form the characteristic pillow shape. This creates a pressure-tight structure with internal channels.

The edges of the pillow plates are trimmed or sealed, and any necessary mounting holes or fittings are added to suit the application.

Each plate undergoes rigorous testing to ensure it meets performance and safety standards before delivery.

This process results in highly efficient, customisable pillow plates. With an eye for quality, our plates ensure long-lasting performance across various industrial systems.

Specifications

Shapes

The welding process necessitates flat sheets of metal in order to create pillow plates. The plates can be laser cut however to any required shape or size. When the welding is finished, the pillow plates can be further formed into shapes by rolling or bending them. This flexibility allows for the creation of curved or contoured surfaces.

Pattern

Thanks to the flexible welding pattern, pillow plates can be designed to create a consistent surface for heating or cooling. The pattern can also be adjusted to increase turbulence, making the plates more efficient heat exchangers.

Material

The most commonly used materials for pillow plates are mild steel and stainless steel, chosen for their durability and excellent thermal conductivity. For specific applications requiring other materials we are happy to discuss your needs.

Size

| Description | Minimum | Maximum | Unit |

| Product Length | 600 23,62 | 6000+ 236,22 | mm inch |

| Product Width | 100 25,4 | 2000 78,74 | mm inch |

| Plate Thickness Bottom plate | 0,8 0,03 | 20 0,31 | mm inch |

| Plate Thinkness Top plate | 0,8 0,031 | 2 0,079 | mm inch |

Do you want more information on your unique project? Contact us below.